- info@ficci.org.bd

- |

- +880248814801, +880248814802

- Contact Us

- |

- Become a Member

- |

- |

- |

- |

- |

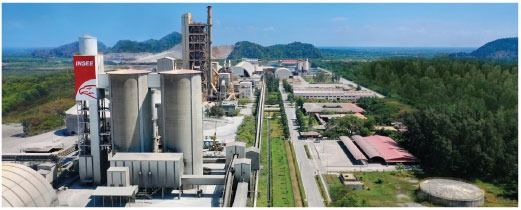

The cement industry of Bangladesh is one of the largest importers by weight, having procured an unparalleled volume of raw material in past years. Cement industry is not only critical to country's construction and infrastructural growth, but it is also interlinked with over 200 small, medium and large sized industries through forward and backward integration.

Cement production in Bangladesh primarily involves grinding raw materials such as clinker, gypsum, limestone, slag, and fly ash. Due to the absence of economically viable limestone reserves within the country, nearly all cement manufacturing facilities operate solely as grinding units, relying on imported raw materials. Currently, only a limited number of coal-based power plants produce fly ash, which is insufficient to meet industry demand. As a result, the cement sector is heavily dependent on imports, with over 85% of raw materials sourced from countries including Thailand, Indonesia, the UAE, India, Pakistan, Oman, China, Vietnam, and Japan. This high reliance on imports makes the industry particularly vulnerable to factors such as port infrastructure, customs regulations, and international freight dynamics. Hence, the industry is vulnerable to freight volatility, supply chain disruptions, and tariff anomalies. As cement forms the base of all infrastructure development, its cost and quality significantly determine the outcomes of construction projects. Consequently, inefficiencies in raw material handling and port operations are directly reflected in project delays and increased construction costs. For example, in 2024 alone, the cement industry imported clinker valued at approximately $877 million. With the right policy and infrastructure reforms such as revising customs assessments and improving port efficiency importers could save at least $2 per ton, translating to $44 million in potential annual savings. This underscores the need for systemic changes across regulatory, logistical, and operational domains.

Clinker, gypsum, and slag are primarily imported through seaports, while the transportation of fly ash and limestone largely depends on inland ports. Chittagong Port, which manages over 90% of Bangladesh's maritime trade, serves as the principal gateway for raw material imports. Although Mongla Port is expanding, it still faces limitations in both capacity and connectivity, currently catering mainly to cement manufacturers located in the southern region of the country. Inland ports such as Hili, Tamabil, and Sheola also play a significant role in sourcing cement raw materials.

Ongoing infrastructure developments such as the expansion of Matarbari Seaport, and inland ports like Sonamasjid, Bhomra, and Pangaon are expected to substantially enhance import capabilities. However, persistent challenges such as port congestion, shallow draft restrictions, and inefficiencies in cargo handling continue to result in elevated demurrage charges and extended vessel turnaround times. According to the Agility Emerging Markets Logistics Index 2024, Bangladesh ranks 36th in terms of international logistics opportunities, with a score of 4.37 out of 10, positioning it relatively low compared to other South Asian emerging economies. As per expert analysis, reducing domestic logistics costs by 17% has the potential to increase Bangladesh's export volumes by around 7.4%. However, poor port infrastructure remains a critical challenge, with approximately 35% of goods reportedly sustaining damage during port handling. The World Bank highlights that further improvements such as decreasing dwell times and marginally enhancing average transport speeds by just one day could lead to additional export growth of 7.4% respectively.

These Bangladeshi ports currently lack the infrastructure to accommodate very large ore carriers (VLOC), ultra-large container vessels (ULOC), or Chinamax ships. This forces dependence on feeder vessels and lighter- age, driving up freight and handling costs. Competing regional ports in Sri Lanka, India, and Myanmar boast superior draft depth, modern cargo-handling equipment, and faster processing placing Bangladesh at a disadvantage in terms of logistics competitiveness.

The Bangladesh Water Transport Coordination Cell (BWTCC) has also drawn criticism for its non-transparent vessel allocation process. Smaller and mid-sized importers often face challenges due to lack of access or favoritism within the system. Cargo delays at outer anchorage due to allocation inefficiencies increase demur- rage and operational costs. Although BWTCC introduced fixed freight rate charts, stakeholders argue they fail to reflect real-time market conditions, creating friction between importers and vessel owners.

Seasonality also profoundly influences import operations. During the dry season, high construction demand increases raw material imports, leading to congestion, delays, and higher demurrage costs. In contrast, the monsoon season affects operational efficiency due to rain-related disruptions, further complicating unloading and handling at ports like Chattogram and Mongla. Such seasonal fluctuations raise logistics costs and reduce overall productivity.

Bangladesh has initiated several regional trade integration efforts to streamline logistics. The Chittagong-Ranong Port MoU signed with Thailand aims to establish a direct maritime route, cutting freight time and cost. This aligns with the broader Bay of Bengal Initiative for Multi-Sectoral Technical and Economic Cooperation (BIMSTEC).

Furthermore, to unlock the full potential of the cement industry and improve trade competitiveness, the following measures are essential:

• Implement a Single Window System: Enable paperless documentation and streamline customs procedures to reduce clearance time.

• Modernize Port Infrastructure: Deepen and dredge port channels to accommodate large vessels, reducing dependence on feeder vessels.

• Expand Berthing & Storage: Increase berth capacity and storage areas to minimize vessel wait times and handling delays.

• Upgrade Equipment: Install high-capacity gantry cranes, mobile harbor cranes, and conveyor systems for efficient bulk handling.

• Digitize Logistics: Develop a unified Port Community System to integrate customs, port authorities, importers/ exporters, and shipping agents.

• Reform BWTCC: Ensure transparency in vessel allocation, reflecting real-time market conditions.

• Incentivize KPIs: Award port handling contracts based on performance indicators such as cost-efficiency, speed, and safety.

The cement industry's critical role in national infrastructure demands a responsive, integrated trade and logistics ecosystem. Addressing challenges across port infrastructure, customs valuation, and seasonal bottlenecks will not only lower input costs but also enhance Bangladesh's industrial competitiveness and regional trade positioning. Strategic investments and policy reforms can turn current vulnerabilities into long-term advantages, ensuring sustainable growth in both construction and manufacturing sectors.